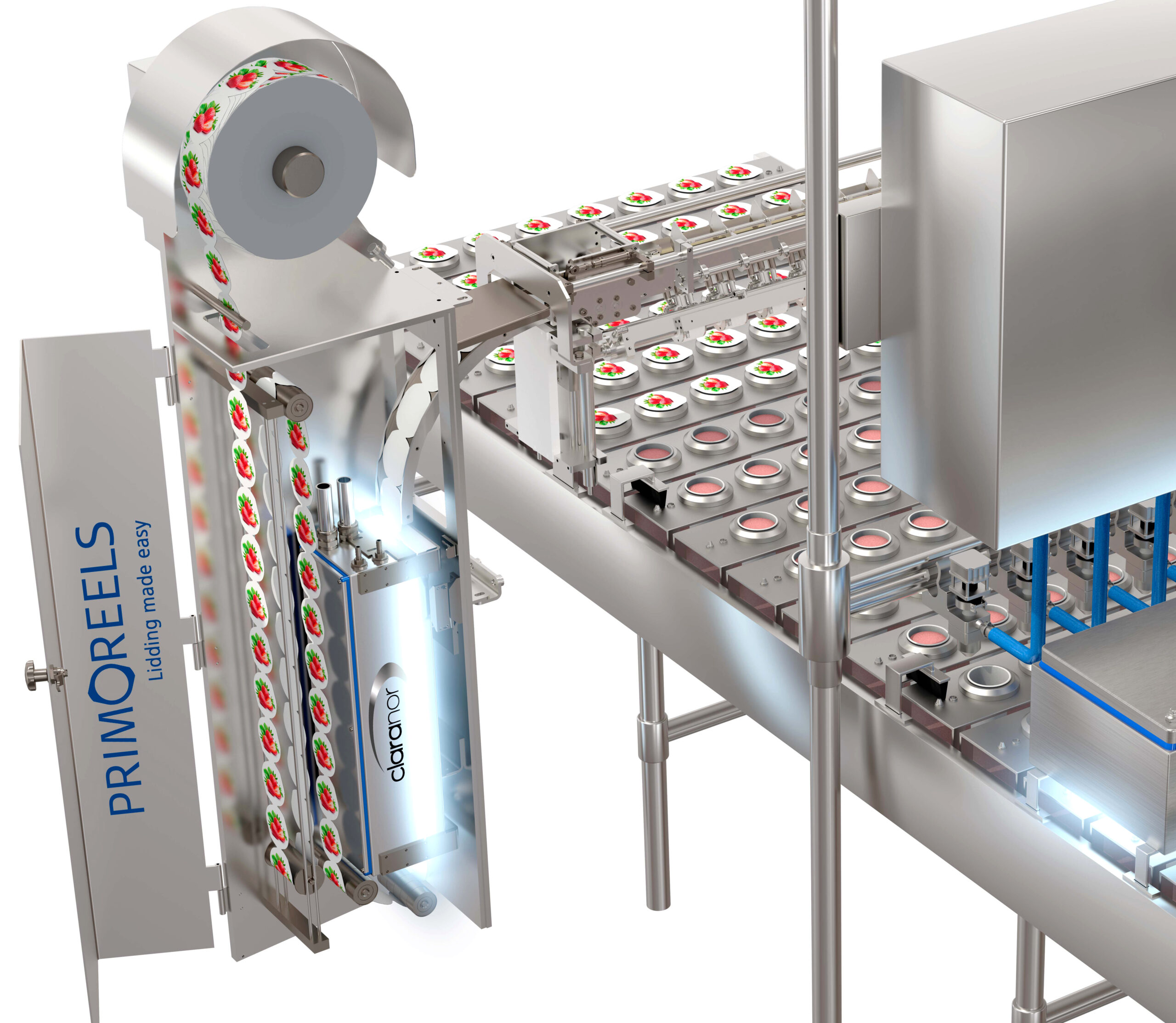

Lidding Made Easy. The lidding system of the future.

60

Years Experience

dynamic lidding systems

We're committed to providing high-quality lidding solutions that meet the needs of our customers.

primoreels lidding solutions

Protect your products from contamination, maintain freshness, and extend their shelf life.

The reason why you should chance your FS-Mashines to Premoreels Lidding System with Claranor decontamination

THIS IS YOUR HIGH INNOVATIVE AND COST-EFFICIENT ADVANTAGES

• Easy integration into your existing filling line with capacities of up to 45 cycles/min.

• Thinner and more sustainable materials which results in lower cost and lower environmental hazards

• High print quality – No embossing needed, so lids are supplied with a completely smooth surface

• Less operator handling – up to 40,000 lids on a reel, and no waste material in the production

• Decontamination safer and easier with Claranor “Pulsed Light” sterilization

Primoreels enables customers to eliminate expensive and wasteful over-capping, and in this way, bring lidding to the next level in terms of efficiency and lower costs.

Primoreels Lidding System

Do you want an alternative solution to the traditional die cut aluminium lids? Primoreels offers a variety of material qualities in the thinnest and most sustainable materials.

PRIMOREELS LIDDING SYSTEM GIVES YOU:

A USER FRIENDLY SYSTEM, Lower margin of error compared with known alternatives. Reels are easy to handle and install, and they only weigh 10-12 kg. so can be handled by the operators.

TAILOR-MADE UNITS, to suit your specific needs. Primoreels deliver a complete lidding solution, with both the dispensing system and the lids used in the system. Primoreels’ systems have their own touch screen panels and controls, making them independent units.

LESS WASTE MATERIAL, No scrap in your production. The only waste from the lids at your facility is the cardboard core itself and the sealed plastic bag in which the reels are delivered.

LOWER RISK OF CROSS CONTAMINATION, Primoreels’ system are untouched by human hands, as opposed to die-cut lids that are manually packed, and fed into the filling machines manually.