Sustainability

Innovation to reduce the unnecessary use of packaging material

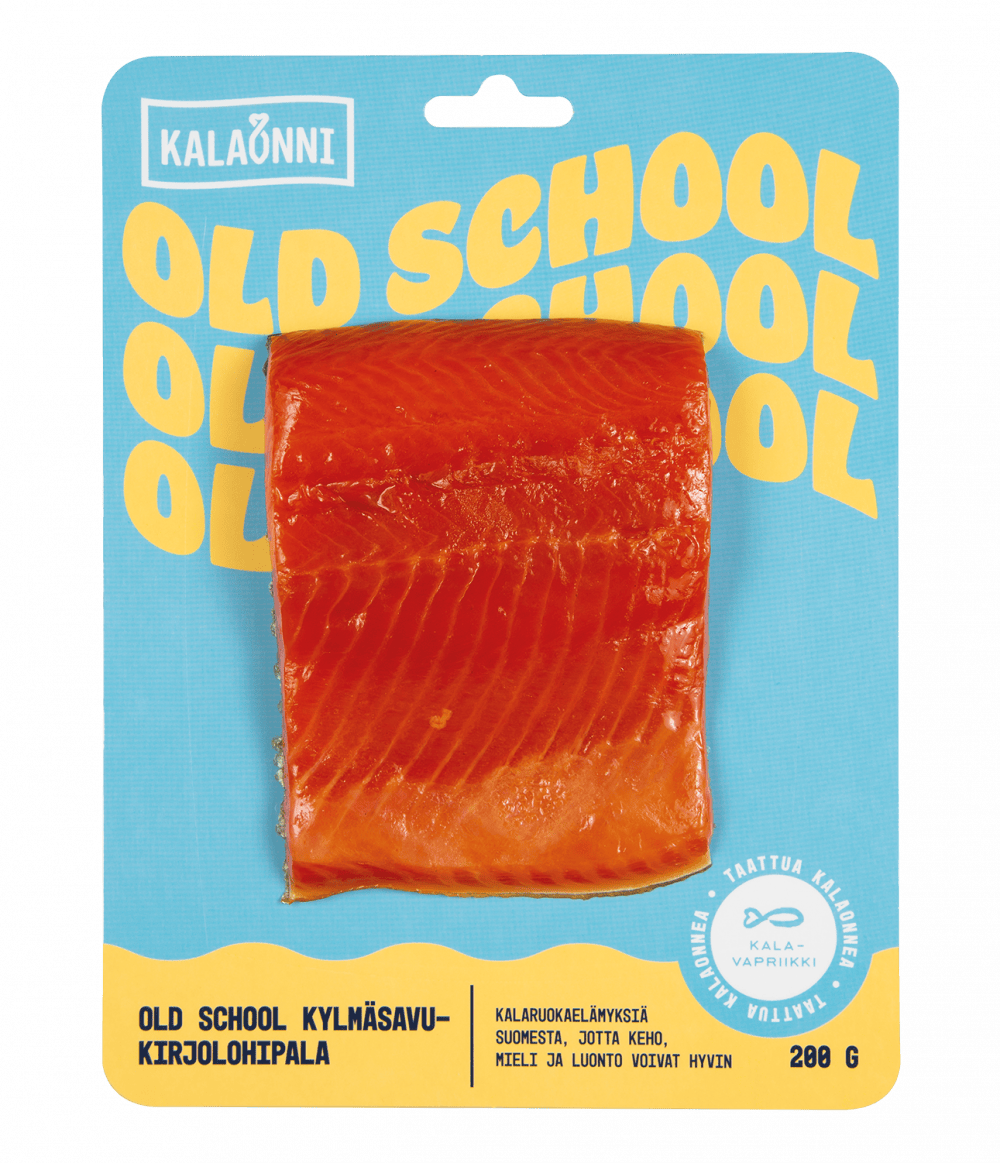

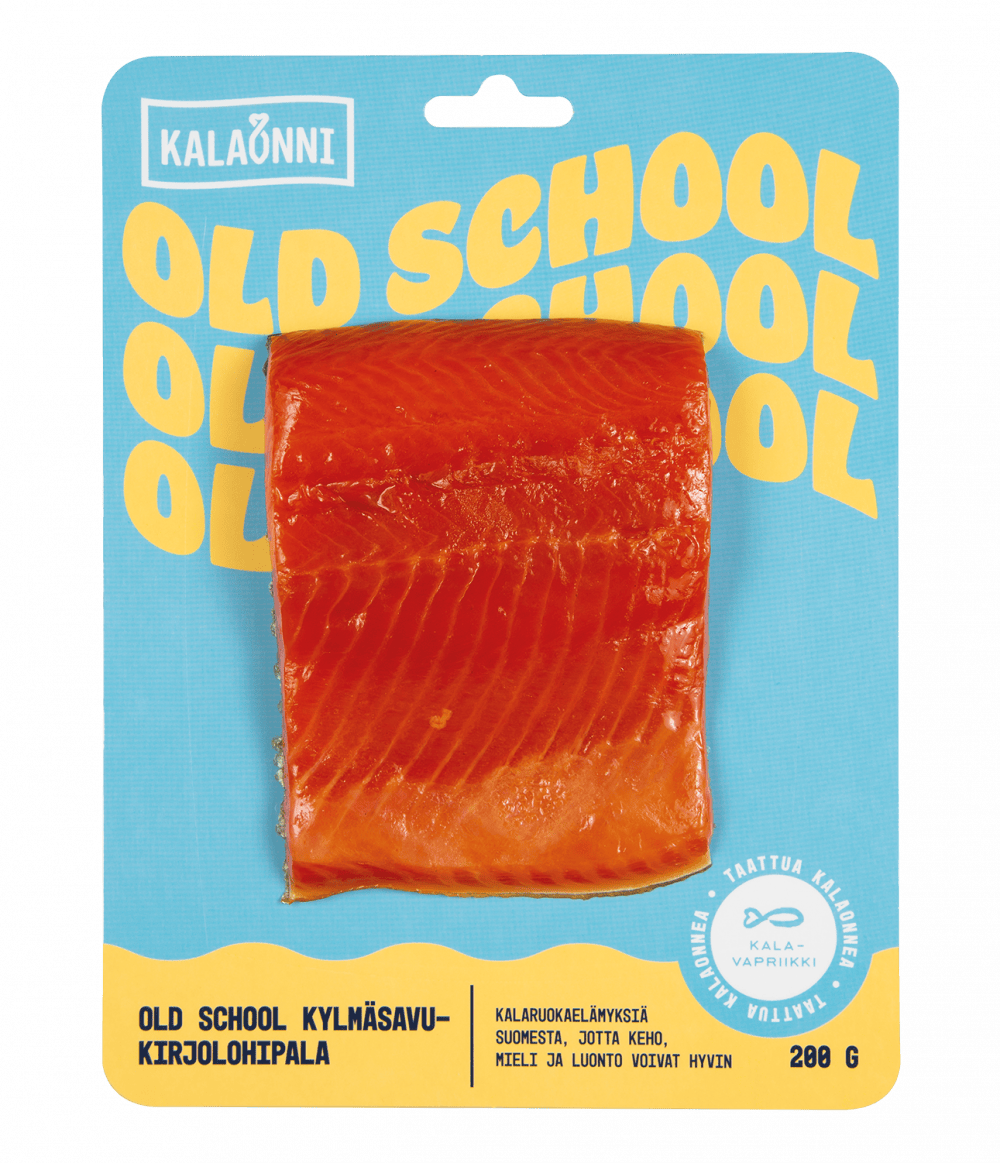

Our Vacuum Skin Packaging solutions are designed to provide efficient and high-quality packaging for a wide range of food products, including meats, poultry, fish, and more. The packaging is designed to preserve the freshness and quality of the food, ensuring that it remains fresh and flavorful for longer periods.

Over 50 years’ experience in designing and building tray sealing systems

MAP delivers extension of the shelf life of fresh food products from a few days to 1, maximum 2 weeks depending on food products and process

Minimise failures leading to unplanned stops thanks to robust construction, trouble-less operation and patented mechanical seal

Complete systems integration that delivers PERFORMANCE and SECURITY

Combination of printed flat cardboard support with thin high barrier films and vacuum skin technology

Experience the seamless fusion of technology and efficiency with G. Mondini designed for precision and reliability.

Vacuum Skin Packaging (VSP) technology removes air and creates a secure seal, significantly extending product shelf life while maintaining freshness and quality

The skin-tight film provides a crystal-clear view of the product, improving visibility and consumer appeal, ideal for premium food items

Solutions like PaperSeal® Skin reduce plastic usage by up to 90%, offering eco-friendly alternatives that support recyclability and meet sustainability goals

Suitable for a wide range of products, including fresh meat, seafood, poultry, dairy, and ready meals, accommodating various industries and market needs

Innovative systems such as the Platformer Skin optimise material use, reduce waste, and lower total pack costs without compromising on quality or performance

G. Mondini provides cutting-edge, reliable packaging technologies trusted by top brands globally

Our Vacuum Skin Packaging machines are designed with efficiency and ease of use in mind. They come equipped with user-friendly controls and intuitive interfaces, making them easy to operate for both experienced and novice operators. They are also designed with safety features to ensure that they are safe to operate, and require minimal maintenance to keep them running smoothly.

Learn More About G.MondiniWorld-class tray sealing technology

Unlock the full potential of your production capabilities with Mondini

This technique uses a high-barrier plastic film over a pre-formed tray, forming a second skin around the product. It’s suitable for various perishable foods and is ideal for freezing applications.

100% top film utilisation, resulting in zero scrap and waste. It provides superior product definition and visibility, with increased packaging speeds compared to standard tray skin methods.

Innovative tray allows brands to replace high-barrier VSP trays with a barrier-lined paperboard alternative, reducing plastic usage by 80-90%. It offers outstanding product display and is designed for easy recycling.

Contact us today to learn about our tray sealing solutions.