Efficiency and Reliability Redefined: The Innovation Behind Trave Tray Sealers

In the world of food packaging, the ideal machine embodies efficiency and reliability—delivering speed, minimising downtime, and ensuring impeccable product quality. Yet, for many packaging systems, these ideals remain elusive. However, the pursuit of excellence has led to groundbreaking advancements in tray sealer technology by G.Mondini, redefining industry standards and achieving unparalleled levels of Overall Equipment Efficiency (OEE).

The Three Pillars of OEE Excellence

Contrary to common perception, OEE is not just about production speed. It’s a multifaceted measure that hinges on three key performance indicators (KPIs) that have been meticulously optimised in modern tray sealers:

- Reliability: The backbone of efficient production is a reliable machine. By minimising maintenance needs and ensuring uninterrupted operation, these sealers achieve consistency and dependability.

- Quality: High standards for every single pack—whether MAP, SKIN, or FRESH—ensure the integrity and safety of the packaged product, meeting even the most stringent consumer and retailer expectations.

- Performance: Uninterrupted and high-speed production keeps operations running at peak efficiency, enabling businesses to meet demanding schedules and scale their output.

Trave: A Masterpiece of Engineering

As Paolo Mondini, Engineer, explains:

“Trave defines who we are. It is a future-oriented driver of value, combining the latest technological innovations with refined engineering for accurate control of product safety and production parameters of the packaging system.”

With over 50 years of expertise distilled into its design, Trave has emerged as the gold standard in food packaging machinery. Its precision engineering, robust construction, and intelligent design make it the epitome of reliability and innovation.

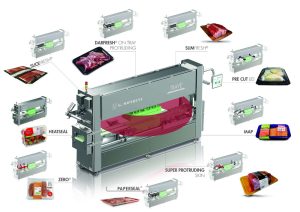

A Machine for Every Need

The Trave range includes eight models, capable of handling a wide variety of production capacities—from small-scale operations producing 10 packs per minute to high-speed lines exceeding 220 packs per minute. This versatility ensures businesses of all sizes can benefit from advanced technology.

Flexibility: The Key to Success

In an industry where consumer preferences and retailer demands are constantly evolving, adaptability is paramount. Trave sets itself apart with its exceptional flexibility:

- Packaging Formats: Seamlessly switch between HEAT SEALING, MAP, and SKIN technologies without compromising speed or quality.

- Material Compatibility: Whether using plastic, aluminium, steel, cardboard, or recycled materials, Trave delivers optimal performance across all raw material types.

Meeting the Challenges of Tomorrow

Science, technology, and innovation are the cornerstones of modern food packaging. As the industry faces new challenges and shifts in consumer behaviour, Trave equips manufacturers with the tools to stay ahead of the curve. Its ability to produce diverse packaging formats and handle sustainable materials ensures businesses can meet demands effectively and responsibly.

Trave: Setting a New Benchmark

From its intelligent design to its superior engineering, Trave stands as a testament to the commitment to excellence in tray sealing. Whether you’re seeking to improve efficiency, reduce downtime, or deliver impeccable quality, Trave provides a solution that is as adaptable as it is reliable.

For companies ready to elevate their packaging operations, Trave isn’t just a machine—it’s a strategic investment in efficiency, flexibility, and the future of food packaging.