lidding

made

easy

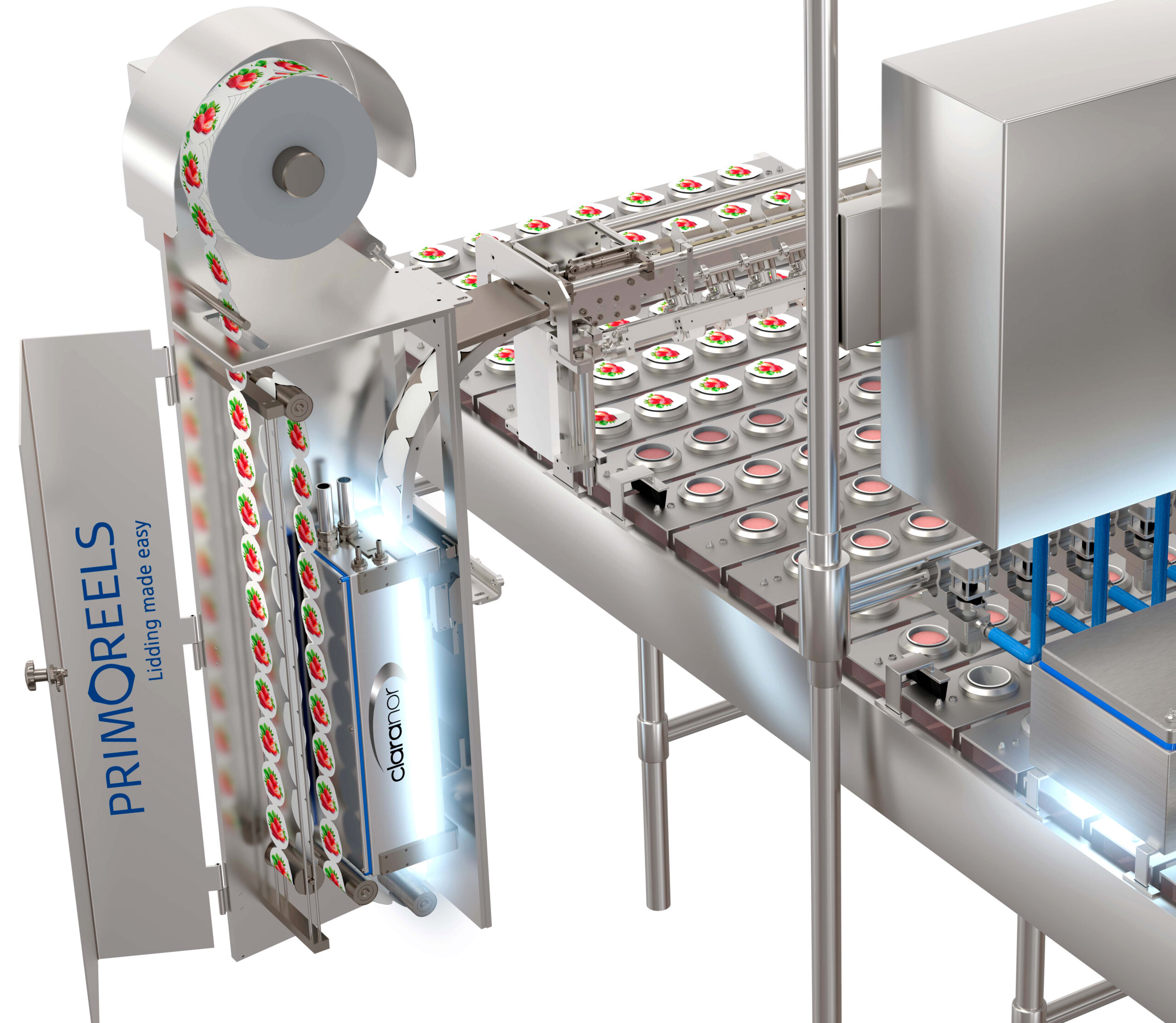

Primoreels sealable lids on reels

The lidding system of the future.

An innovative solution for applying sealable lids to cups using the thinnest and most sustainable materials available!

Looking to cut waste without compromising quality? Primoreels® technology delivers sealable PET lids as thin as 23 microns – designed to help producers:

Perfect for yoghurt and dairy packaging, our sealable lids keep your product protected, your line efficient, and your brand aligned with today’s sustainability goals.

Lidding made easy with lids on reels

Our reel-based lid systems deliver cost-effective performance by seamlessly integrating into existing filling machines —helping manufacturers slash waste, boost hygiene and reduce total packaging cost.

Lower CO2 impact

Reduce your carbon footprint Reduced environmental impact from storage and freight

Better hygiene and food safety

UV treatment tunnel as a standard, in which the lids can be treated easily and inexpensively

Improved experience

Saving manpower in your production - Primoreels system means quicker and less frequent refills

Easy to install

Can be adapted to any type and brand of filling machine – old or new

Alternative to traditional die cut aluminium lids

Primoreels Lidding In Action

Primoreels offers a variety of material qualities in the thinnest and most sustainable materials

Features

Today the Primoreels System is considered by many customers to be the lidding system of the future.

Integration

Easy integration into your existing filling line with capacities of up to 45 cycles/min and up to 40,000 lids on a reel, and no waste material in the production

Lower Costs

Thinner and more sustainable materials which results in lower cost and lower environmental hazards

Print Quality

High print quality – No embossing needed, so lids are supplied with a completely smooth surface

Lower cross contamination

Primoreels’ system are untouched by human hands, as opposed to die-cut lids that are manually packed, and fed into the filling machines manually

Sterilisation

Decontamination safer and easier with Claranor “Pulsed Light” sterilisation

User Friendly System

Lower margin of error compared with known alternatives. Reels are easy to handle and install, and they only weigh 10-12 kg so can be handled by the operators

thinnest and most sustainable materials

Seal Smart. Waste Less

Sustainable sealing without compromise.

Primoreels’ metalised PET lids deliver:

- 67% lower emissions

- 56% less energy use

- 55% less waste

Compared to aluminium lids, they reduce environmental impact while enhancing product quality through premium printability, puncture resistance, and sterilisation performance.

DAIRY LINE

Primoreels with Primodan

Primoreels in conjunction with Primodan A/S = the perfect dairy line solution

Reach out today

Contact us today to learn about our lidding solutions.